Did you know that a staggering 40% of severe burn injuries in some regions are linked to kerosene stove accidents? These incidents are not random but are predictable consequences of improper maintenance, fuel adulteration, and equipment failure. This definitive guide delivers the critical knowledge and step-by-step protocols you need to transform your kerosene stove from a potential hazard into a safely managed appliance, covering everything from daily cleaning to long-term risk mitigation and carbon monoxide prevention.

【Understanding the Risks: Why Proper Maintenance Matters】

The Alarming Statistics of Kerosene Stove Accidents

Kerosene Stove Burn Injury Data

The statistics paint a clear and urgent picture of the dangers posed by improperly maintained kerosene stoves. Across the Indian territory, a staggering 40% of all burn injuries are directly attributed to kerosene stove explosions. These are not random acts of misfortune; they are predictable consequences of specific, identifiable failures. The root causes consistently point to a trifecta of risk: overpressure within the fuel tank, the use of nonstandard or substandard equipment and fuel, and the unchecked progression of corrosion. Compounding this problem is the fact that a significant number of stove manufacturers, particularly of older or cheaper models, do not integrate adequate, failsafe pressure-release mechanisms, placing the entire burden of safety on the user.

Common Kerosene Stove Hazards

Primary Causes of Malfunction

Understanding how these accidents happen is the first step toward preventing them. The primary causes of stove malfunction are often a result of user error and the inevitable wear and tear on the device.

- Fuel Adulteration: In an effort to reduce costs, kerosene is sometimes mixed with other, more volatile spirits and chemicals. This is an extremely hazardous practice. These adulterants have a much lower flash point than kerosene, meaning they can vaporize and ignite at much lower temperatures, creating a high risk of uncontrolled flare-ups or even explosion within the fuel tank.

- The “More Pump, More Heat” Fallacy: A common and dangerous misconception is that excessive pumping directly equates to higher cooking efficiency. In reality, over-pumping creates dangerously high internal pressure. This forces an excessive amount of fuel vapor through the burner, which can result in a large, unpredictable flame, a fireball upon lighting, or a leak in the fuel line. The correct operation involves pumping only enough to achieve a steady, blue flame.

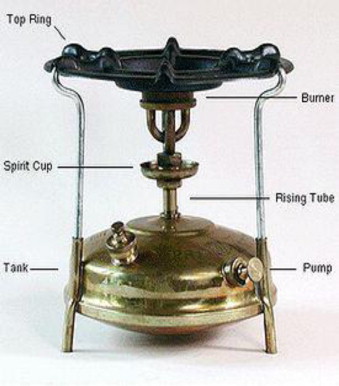

- Corrosion and Poor Maintenance: A kerosene stove is a mechanical device subject to corrosion and degradation. The fuel tank, both inside and out, can rust, leading to pinhole leaks that release flammable vapor. The leather seal on the plunger can wear down, losing its ability to maintain pressure. Clogged burners or wicks from soot and debris can cause uneven burning and flare-ups. Ignoring this gradual wear and tear is a recipe for failure.

For those seeking a safer alternative, modern solutions like the 2025 EcoBlaze Portable Stove offer advanced safety features, including an automatic pressure regulation valve. Learn more and see user reviews at:

【Essential Cleaning Protocol for Kerosene Stoves】

The alarming statistics of stove-related accidents underscore a critical truth: safety is not a passive state but an active practice. The most effective way to mitigate the risks of overpressure, flare-ups, and leaks is through a disciplined and informed cleaning regimen. A well-maintained stove is a safer stove. This protocol, broken down into daily and weekly tasks, is your first line of defense.

Daily Cleaning and Maintenance Routine

Consistency is key. Integrating these simple checks into your daily cooking routine takes only minutes but drastically reduces the chance of malfunctions.

Burner Nozzle Maintenance

The burner nozzle is the heart of the flame. A clogged or partially blocked nozzle is a primary cause of uneven, sooty, and dangerously unpredictable flames.

- Use Only the Specified Pin: Every stove is equipped with a specific cleaning pin. Using improvised tools like wires, needles, or toothpicks can permanently damage the precise orifice of the nozzle, leading to improper fuel vaporization. Gently insert and remove the designated pin to clear any carbon buildup only when the stove is completely cool.

- Prevent Clogging for Efficient Combustion: Regular cleaning after each use or before starting a new one prevents the accumulation of soot and carbon. A clean nozzle ensures efficient combustion, characterized by a steady, blue flame. A yellow or flickering flame is a clear sign of a clog and must be addressed immediately.

- Periodic Burner Replacement: Even with meticulous cleaning, burners degrade over time. For optimal efficiency and safety, plan to replace the stove burner periodically, as recommended by the manufacturer. A worn-out burner will never perform correctly.

Tank Cleaning Procedures

The fuel tank’s integrity is paramount to preventing the overpressure scenarios discussed earlier. Contamination is a silent threat.

- Periodic Tank Cleaning and Rinsing: Over time, sediment, moisture, and microbial growth (known as “kerosene algae”) can accumulate in the tank. This debris can clog the fuel line and burner. Periodically, empty the tank completely and rinse it with a small amount of fresh, clean kerosene. Swirl it around and dispose of the residue safely. Never use water.

- Use Only Filtered Kerosene: This is non-negotiable. Always pour kerosene through a fine mesh filter or a dedicated filtering funnel when filling the tank. This single step prevents the introduction of particulate contaminants that cause blockages and erratic burner performance.

- Ensure a Properly Sealed Filling Cap: Before and after every use, verify that the kerosene filling cap is clean, undamaged, and screws on firmly. A compromised seal will allow pressure to escape, making the stove difficult to light and operate, and can leak flammable vapors into your environment.

Weekly Deep Cleaning Checklist

Once a week, or before extended use, set aside time for a more thorough inspection. This is your opportunity to catch small problems before they become emergencies.

Comprehensive Heater Inspection

- Check for Damage, Rust, or Corrosion: Visually inspect the entire stove body, legs, and fuel tank. Pay close attention to welds and joints. Any sign of rust, particularly on the tank, is a serious concern as it can weaken the metal and lead to pinhole leaks. Surface rust on non-critical parts can be gently brushed off.

- Verify No Leaks Are Present: With the tank pressurized (but the stove not lit), carefully check all fittings, the fuel line, and the base of the tank for any signs of weeping or leaking kerosene. The smell of fuel when the stove is not in use is a major red flag.

- Ensure Air Pump Integrity: The air pump is the source of your stove’s pressure. Check that the plunger moves smoothly. The most critical component is the leather seal on the plunger head; it must be supple and create a firm seal. A worn, cracked, or dried-out seal will make it impossible to build proper pressure, leading to the dangerous “over-pumping” fallacy. A drop of oil can help maintain the leather.

Adhering to this protocol significantly enhances safety. For those seeking a modern stove designed to eliminate many of these maintenance challenges, the 2025 EcoBlaze Portable Stove features a corrosion-resistant tank and a self-cleaning burner nozzle. Explore its full range of safety innovations at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Fuel Safety Guidelines: The Foundation of Safe Operation】

A meticulously cleaned stove can still be a source of danger if the fuel that feeds it is compromised or mishandled. The quality of your kerosene and the protocols for its storage and handling are not secondary concerns; they are the bedrock of safe operation, directly impacting air quality, combustion efficiency, and fire risk.

Proper Fuel Selection and Handling

The single most important decision you make for your stove’s safety and performance happens before you even light it: the choice of fuel.

K-1 Kerosene Benefits and Standards

Not all kerosene is created equal. For indoor heating and cooking appliances, only one grade is acceptable: K-1 Kerosene. This specification is defined by a stringent chemical composition, most notably a maximum sulfur content of 0.04%. This ultra-low sulfur level is critical for two primary reasons:

- Clean Burning for Health: When burned, sulfur converts to sulfur dioxide (SO₂), a toxic gas that can cause respiratory irritation and aggravate existing conditions like asthma. K-1 fuel minimizes these harmful emissions, making it the only safe choice for use in enclosed or poorly ventilated spaces.

- Reduced Odor and Soot: The low sulfur content, along with the high purity of K-1, results in a significant reduction in the characteristic kerosene odor and the production of black, unburned carbon soot. A sooty flame is not just dirty; it’s a sign of incomplete combustion and an indicator that you may be using an improper fuel.

Using anything other than clear, water-white K-1 kerosene—such as diesel, “off-road” fuels, or lower-grade kerosenes—will damage your stove, create unsafe levels of indoor air pollution, and dramatically increase the risk of flare-ups and clogging.

Safe Kerosene Storage Protocols

How you store your fuel is as important as the fuel itself. Proper storage prevents degradation and contains potential hazards.

- Use Approved Containers: Kerosene must always be stored in containers specifically designed and certified for that purpose. These are typically made of high-density polyethylene and are colored blue to distinguish them from containers for gasoline (red) or diesel (yellow). This color-coding is a critical safety measure to prevent catastrophic misfueling.

- Designate a Safe Storage Location: Store kerosene containers in a separate, well-ventilated storage area detached from the home, such as a garage or shed. The primary goal is to keep fuel vapors, which are heavier than air and can travel along the ground, out of your primary living spaces. Never store kerosene in a basement or living area.

- Limit Quantity and Rotate Stock: Store only the amount of fuel you expect to use within a few months. Over time, kerosene can absorb water from the air (a process called hydrolysis), leading to microbial growth and tank contamination. Use older fuel first.

Fuel Spill Prevention and Management

A spill during refueling is a moment of high risk. A disciplined procedure eliminates this hazard.

Safe Refueling Procedures

This is a non-negotiable ritual that must be followed every single time.

- Refuel Outdoors, Always: The entire refueling operation must be conducted outside, in a well-ventilated area, and away from any ignition sources, including pilot lights from water heaters. This simple step ensures any spilled fuel or released vapors dissipate harmlessly into the open air.

- Confirm the Stove is Cold and Off: Before moving the stove to refuel, ensure the flame is completely extinguished and the stove body, especially the fuel tank, is cool to the touch. Refueling a warm or hot stove can cause the remaining fuel to vaporize instantly, creating a highly flammable atmosphere and potential for a flash fire.

- Utilize a Siphon Pump: The safest way to transfer fuel from a storage container to the stove is by using a manual siphon pump. This method provides superior control over the flow of fuel, virtually eliminating the risk of overfills and spills that can occur when pouring directly from a heavy can. It is a simple, inexpensive tool that is a cornerstone of spill prevention.

For those seeking a stove that integrates modern safety with this foundational fuel knowledge, the 2025 EcoBlaze Portable Stove is designed to work optimally with pure K-1 kerosene and features a wide, spill-resistant filler neck. Discover its user-centric safety features at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Carbon Monoxide Prevention and Ventilation Requirements】

While proper fuel selection and handling form the first line of defense, the operational environment of your kerosene stove is the second. The combustion process, even with the purest K-1 kerosene, consumes oxygen and produces byproducts, the most dangerous of which is carbon monoxide (CO). Managing this reality is not optional; it is a matter of life and safety.

Indoor Air Quality Management

A kerosene heater is an oxygen-consuming appliance. Its safe operation is entirely dependent on a continuous supply of fresh air to support complete combustion and to disperse any minor emissions. A sealed, modern home can become a dangerously airtight box without deliberate intervention.

Ventilation Requirements for Safe Operation

The rule is simple and absolute: you must provide a permanent source of fresh, outdoor air whenever the stove is in use.

- Provide a Fresh Air Source: This is most effectively achieved by opening a window or a door in the same room where the heater is operating. The opening need not be large; an gap of approximately one inch is generally sufficient to create the necessary cross-ventilation. This opening should be maintained for the entire duration of the heater’s operation.

- Oxygen Consumption Requires Replacement: The flame inside your stove requires a steady flow of oxygen to burn the fuel cleanly and efficiently. In an enclosed space, the heater will gradually deplete the available oxygen. Without a fresh air supply, the combustion becomes incomplete, leading to a sharp increase in the production of carbon monoxide and soot.

- Proper Ventilation Prevents Buildup: The primary function of this constant air exchange is to prevent the dangerous accumulation of carbon monoxide. The fresh air inflow dilutes any trace CO produced and carries it safely out of the living space, ensuring the air you breathe remains safe.

Carbon Monoxide Detection and Prevention

Ventilation is your proactive measure, but given the stakes, a passive, always-active monitoring system is your essential backup. Carbon monoxide is often called the “silent killer” for a reason.

Essential Safety Equipment

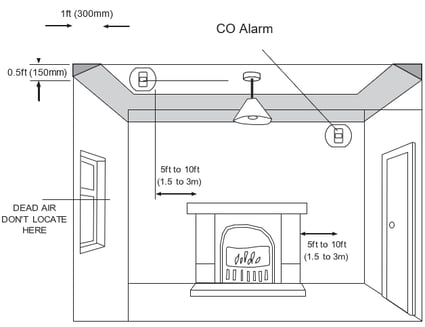

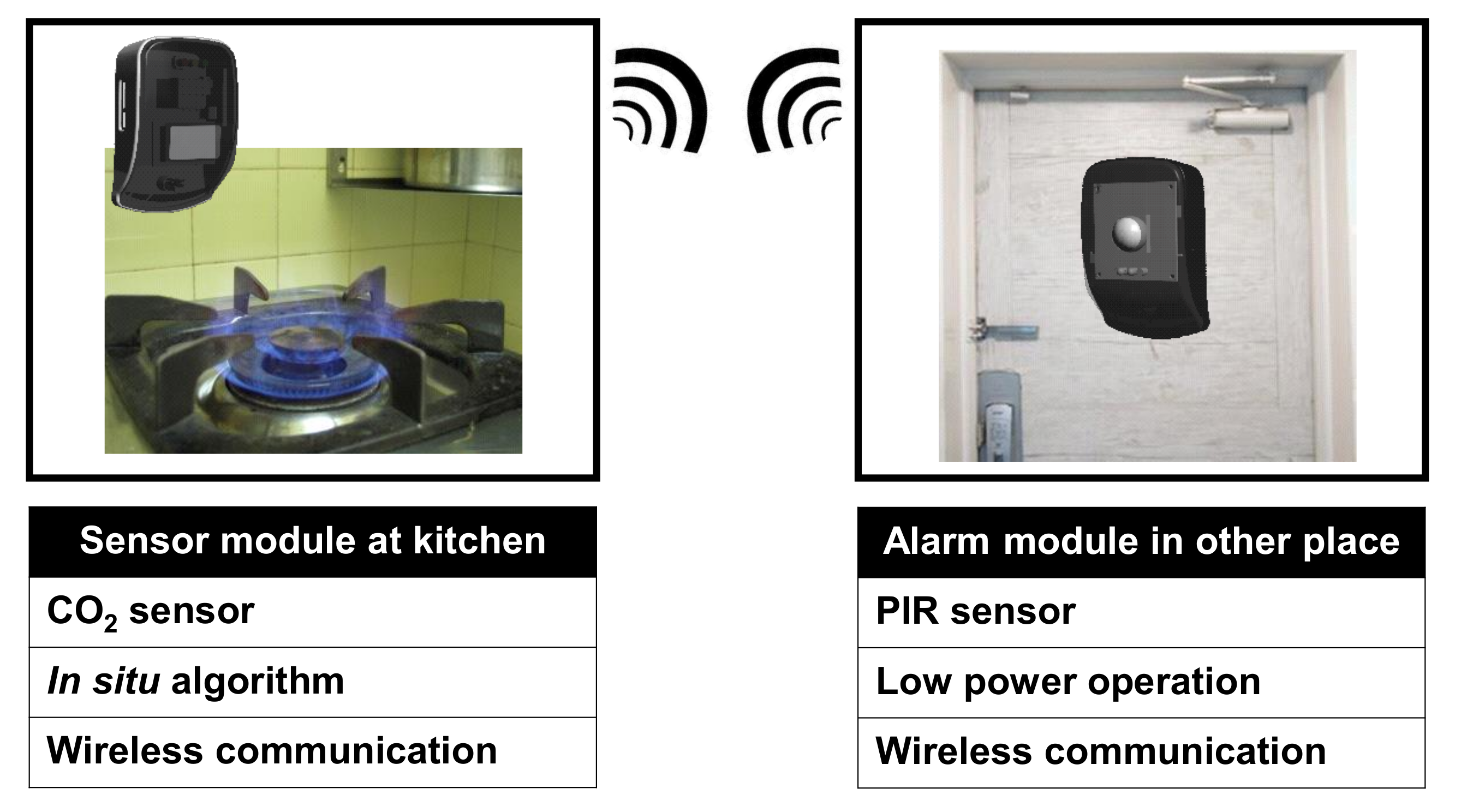

Your kerosene stove and a carbon monoxide detector are an inseparable pair. One cannot be used without the other.

- Always Operate with a Working CO Detector: A battery-operated or plug-in carbon monoxide detector with a digital display should be installed in the same room as the kerosene stove. Test its batteries monthly and replace the entire unit according to the manufacturer’s expiry date, typically every 5-7 years. This device is your final, critical safety net.

- CO is an Invisible, Odorless Threat: Carbon monoxide is a poisonous gas that is completely undetectable by human senses. It binds to hemoglobin in your blood more effectively than oxygen, leading to oxygen deprivation, which can cause unconsciousness and death with little to no warning. Symptoms of low-level exposure, such as headache, dizziness, and nausea, are often mistaken for the flu.

- Modern Heaters Minimize Production: It is important to note that a properly maintained and correctly fueled kerosene stove, operating with adequate ventilation, produces very low levels of carbon monoxide. Modern wick-based heaters are engineered for clean-burning technology, which, when combined with K-1 kerosene, promotes near-total combustion, thereby minimizing CO production as a matter of design. However, “minimized” is not “eliminated,” making the detector non-negotiable.

For homeowners seeking peace of mind, modern stoves are increasingly designed with safety at their core. The 2025 EcoBlaze Portable Stove, for instance, not only operates with high combustion efficiency for low emissions but also features an optional integrated CO sensor that can provide an added layer of monitoring. Explore its advanced safety engineering here: https://www.ecoblaze-stoves.example/kerosene-safety.

【Fire Prevention and Emergency Preparedness】

A clean and well-maintained stove is a safer stove, but its physical placement and the environment around it are equally critical to preventing the most immediate danger: fire. The principles of fire prevention are straightforward, yet their consistent application is what separates safe operation from catastrophe.

Fire Prevention Strategies

The goal is to create a controlled, isolated zone for the heater’s operation, where its radiant heat and open flame cannot interact with anything that can burn. Complacency is the primary enemy here; a space that seems safe can quickly become hazardous if these boundaries are not rigorously maintained.

Clearance and Placement Guidelines

The three-foot rule is the non-negotiable foundation of kerosene stove safety. This distance must be measured in all directions—front, back, sides, and above—from any part of the stove.

| Object to Avoid | Minimum Clearance | Rationale |

|---|---|---|

| Furniture, Curtains, Bedding | 3 feet (1 meter) | Prevents radiant heat from igniting common household combustibles. |

| Walls & Cabinets | 3 feet (1 meter) | Prevents heat buildup and potential ignition of wall materials. |

| Papers & Clothing | 3 feet (1 meter) | These lightweight, flammable items can be ignited by a single spark or intense radiant heat. |

| Children & Pets | 3 feet (1 meter) | Creates a safety buffer to prevent accidental contact burns or tipping. |

Furthermore, the stove must only be operated on a stable, level, and non-flammable surface. A tile floor, a concrete basement slab, or a dedicated hearth pad are ideal. Never place the unit on a wooden table, a carpet, or vinyl flooring that could melt or burn. When cooking, avoid using oversized pots or kettles that can extend beyond the stove’s guard and are prone to tipping, potentially directing the flame onto the handle or surrounding materials.

Emergency Heating Solutions and Backup Planning

For many, a kerosene stove is not merely a convenience but a vital piece of emergency equipment, providing life-sustaining heat during a winter power outage. In this role, its reliability is paramount, and that reliability is a direct product of diligent maintenance and preparation.

Winter Heating Safety Protocols

A kerosene heater offers invaluable off-grid heating capability, but using it safely in an emergency requires pre-planning. The chaos of a power failure is not the time to discover your stove is clogged with old fuel or that your fuel has degraded.

- Proper Maintenance Ensures Emergency Readiness: The cleaning and maintenance rituals described earlier are your guarantee that the stove will start and operate safely when you need it most. A stove with a dirty wick or a tank contaminated with sludge will be unreliable at best and dangerously inefficient at worst.

- Cold Weather Preparedness Includes Fuel Rotation: Storing a sealed container of fresh, clear K-1 kerosene is a key part of a winter preparedness kit. Fuel should be rotated, using the oldest stock first, to ensure it burns cleanly. Water condensation in stored fuel tanks is a common cold-weather issue that can be mitigated by using fuel stabilizers and keeping containers full to minimize air space.

- Pre-Season Equipment Testing: Before the heating season begins, and certainly before an anticipated storm, conduct a full test of your equipment. This includes cleaning the stove, inspecting the wick, filling it with fresh fuel, and operating it outdoors for a short period to ensure it lights and burns correctly with a steady, blue flame. This practice run confirms your readiness and familiarizes you with the startup procedure under calm conditions.

For those who rely on their stove for emergency heat, choosing a model designed for reliability is crucial. The 2025 EcoBlaze Portable Stove is engineered not only for clean combustion but also for long-term storage readiness, with a corrosion-resistant tank and a precision wick mechanism that resists clogging. Its robust design makes it a dependable core of any family’s emergency plan. Learn more about its features for reliable backup heating: https://www.ecoblaze-stoves.example/kerosene-safety.

【Troubleshooting Common Kerosene Heater Issues】

A well-maintained stove is a reliable one, but even with diligent care, performance issues can arise. Learning to diagnose these problems is a critical aspect of safe operation, as many common symptoms are not mere inconveniences but signals of potentially hazardous conditions. Addressing them promptly and correctly ensures your heater remains an efficient source of warmth rather than a source of pollution or danger.

Performance Problem Diagnosis

The flame of a kerosene heater communicates its state of health. A properly functioning stove will produce a quiet, steady, blue-to-yellow flame with minimal visible smoke or odor. Deviations from this are key indicators of an underlying issue that requires attention.

Identifying and Resolving Common Issues

- Strong Odor: A persistent, sharp kerosene smell during operation is a common complaint and a significant safety concern. This almost always indicates one of two problems. First, and most critically, the use of the wrong fuel type, such as gasoline or “clear” diesel, which have lower flashpoints and produce toxic, explosive vapors. Only ever use 1-K grade kerosene. Second, a dirty or clogged wick that is not drawing fuel properly can cause incomplete combustion at the base, leading to raw fuel vaporizing and escaping into the room. The solution is to extinguish the stove, let it cool completely, and trim the wick to expose fresh, porous material, or replace it entirely if cleaning is ineffective.

- Black Smoke: The production of thick, black soot (smoke) is an unambiguous sign of incomplete combustion. This occurs when the fuel-to-air ratio is incorrect. The most frequent cause is a wick that has been adjusted too high, creating an overly rich fuel mixture that cannot burn cleanly. Lowering the wick height will typically resolve this. If the problem persists, the fuel itself may be contaminated with dirt, water, or algae, or the wick may be old and carbonized, unable to draw fuel correctly. In these cases, draining the tank and refilling with fresh 1-K kerosene and replacing the wick is necessary.

- Difficulty Lighting: If the stove is hard to light or the flame will not travel evenly across the wick, the wick is the primary culprit. Over time, the top of the wick becomes hardened with carbon deposits, forming a crust that prevents the capillary action needed to draw fuel to the tip for ignition. While minor crust can be scraped away, persistent difficulty lighting typically requires a full wick replacement. A wick that is frayed, damaged, or has absorbed contaminants will also fail to light properly.

Heater Inspection Checklist

Transitioning from reactive troubleshooting to proactive inspection is the hallmark of responsible ownership. A systematic pre-season check, conducted before you need to rely on the heater, ensures it will operate safely and efficiently throughout the cold months.

Pre-Season Maintenance Protocol

Before the first use of the season, follow this checklist to verify your heater’s condition:

- Inspect the Wick: Carefully remove the wick assembly and examine it thoroughly. Look for any signs of hardness or heavy carbon buildup at the top. Check the edges for fraying, unraveling, or an uneven surface. A good wick should be uniformly fibrous and pliable. If you detect any hardness, significant carbon deposits, or frayed edges, replace the wick. Do not attempt to operate the stove with a compromised wick.

- Clean Inside and Outside: With the wick removed, use a vacuum with a soft brush attachment to gently remove any accumulated dust, lint, or cobwebs from the inside of the burner assembly and the fuel tank area. Wipe down the entire exterior of the stove with a damp cloth to remove surface grime. Pay special attention to the vents and air inlets, as blockages here will disrupt the air supply needed for clean combustion.

- Verify Anti-Tip Shutoff Mechanisms Function Correctly: This is a critical safety test. On a stable, level surface, carefully tilt the stove to the side (without fuel in it, if possible). You should hear a distinct click as the tip-over safety switch engages, which would normally snuff out the flame. Test this from multiple angles. If the mechanism is sluggish, stuck, or fails to activate, the stove must be serviced by a qualified technician before use.

For homeowners seeking a heater that simplifies maintenance, the 2025 EcoBlaze Portable Stove features a quick-disconnect wick assembly for easy inspection and a built-in diagnostic indicator that alerts users to common performance issues. Its design prioritizes long-term reliability with minimal fuss. For a detailed look at its maintenance features, visit: https://www.ecoblaze-stoves.example/kerosene-safety.

【Long-Term Maintenance and Safety Compliance】

Transitioning from seasonal troubleshooting to a long-term perspective is what separates adequate maintenance from true stewardship of your equipment. The longevity and, more importantly, the ongoing safe operation of a kerosene stove are not merely functions of how you clean it, but of the fundamental choices you make regarding its fuel and the integrity of its physical construction. Adhering to a strict, evidence-based protocol in these areas is the most effective way to prevent performance degradation and mitigate long-term risks.

Fuel Quality Standards and Equipment Longevity

The fuel you choose is the lifeblood of your stove, and its quality directly dictates the health of the entire system. Compromising on fuel standards is a decision that guarantees a cascade of operational and safety problems over time.

Ensuring Clean Burning Fuel Performance

The single most critical rule for kerosene heater maintenance is the exclusive use of high-purity, water-clear 1-K grade kerosene. This specification is not a suggestion but a requirement for the safe and efficient operation of indoor, unvented appliances.

- Use only K-1 Kerosene: 1-K grade kerosene is refined to a much higher standard than other grades, with severely limited sulfur content and impurities. This purity is essential for complete combustion, which minimizes the production of carbon monoxide, sulfur dioxide, and fine particulate matter (soot) that can pollute your indoor air and coat the interior of your stove.

- Avoid Red-Dyed Kerosene: It is imperative to avoid red-dyed kerosene, which is typically 2-K grade. This fuel contains significantly higher levels of sulfur and other contaminants. While it may be acceptable for certain outdoor or industrial equipment, burning it in an indoor heater releases harmful levels of sulfur dioxide—a corrosive gas that is hazardous to health and damaging to the stove’s internal components. The dye itself can also contribute to wick clogging.

- Prevent Contamination and Damage: Using improper or contaminated fuel is a primary cause of wick contamination and damage. Impurities do not burn cleanly; instead, they bake onto the wick’s fibers, creating a hardened, carbonized crust that impedes capillary action. This leads to the very performance issues—difficulty lighting, strong odors, and black smoke—that shorten the wick’s lifespan and compromise the stove’s safety. Proper fuel selection is the first and most effective form of preventative maintenance.

Structural Integrity and Material Standards

The physical design and materials of a kerosene stove are not arbitrary; they are the result of rigorous safety engineering intended to contain high temperatures and flammable liquid. Any deviation from these standards introduces unacceptable risk.

Equipment Safety Verification

Before even considering the operation of a kerosene stove, a thorough inspection of its physical construction is non-negotiable. This verification ensures the basic safety systems are intact.

- Only Metal Body Construction: A certified kerosene stove for indoor use must feature a body and critical components constructed primarily of metal. The use of fiber, plastics, or rubber in the main body or combustion chamber is a severe safety violation. These materials cannot withstand the operating temperatures of the stove and can melt, warp, or ignite, leading to a structural failure and fire. Always verify that your stove is of all-metal construction where it counts.

- No In-House Modifications: Under no circumstances should any user-made modifications be performed on a kerosene stove. This includes drilling new air holes, altering the wick adjustment mechanism, or attempting to “fix” a damaged fuel tank. Such modifications irrevocably compromise the engineered safety margins of the appliance, potentially leading to uncontrolled flames, fuel leaks, or catastrophic failure. If a stove is not functioning correctly with proper maintenance, it should be serviced by a qualified professional or replaced.

- Double Burner Stove Safety: While available on the market, double-burner kerosene stoves are generally not recommended for residential safety reasons. Their design often results in a significantly higher heat output and fuel consumption rate within a single unit, which can more rapidly deplete oxygen in a room and increase the concentration of combustion by-products if adequate ventilation is not strictly maintained. For most home environments, a single, properly sized burner is the safer and more manageable choice.

For those prioritizing long-term safety and compliance, the 2025 EcoBlaze Portable Stove is engineered to these exacting standards. Its body is constructed entirely from certified high-grade steel, and it is designed to operate exclusively and efficiently with 1-K kerosene, featuring a fuel system that resists contamination. To review its construction and material specifications, you can find more information at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Creating a Comprehensive Safety Culture】

Adherence to fuel and material standards forms the foundation of kerosene stove safety, but it is the daily, habitual practices of the user that ultimately determine risk levels. A safety culture is not a checklist but a consistent mindset, where vigilance and preparedness become as routine as lighting the stove itself. This involves embedding safe operating habits into every use and having a clear, practiced plan for the unlikely event of an emergency.

Developing Safe Operating Habits

The greatest safety feature of any appliance is an attentive and educated operator. Safe habits are simple to learn but must be applied without exception to be effective.

Routine Safety Practices

Establishing and strictly following a set of core rules mitigates the most common and dangerous scenarios associated with kerosene stove use.

- Never leave an operating heater unattended or running during sleep. An active stove requires active supervision. You must be present and alert to notice any changes in flame pattern, odor, or performance. A stove should be extinguished before leaving the room for an extended period and always before any occupant falls asleep. The risks of a malfunction in an empty or sleeping household are catastrophic.

- Perform kerosene stove cooking only on stable, non-flammable surfaces. The ideal location is a dedicated kitchen countertop or platform made of stone, tile, or metal. The stove must be placed well away from curtains, wooden cabinets, paper towels, or any other combustible materials. A minimum clearance of three feet from any wall or flammable item is a prudent rule. This prevents accidental ignition from radiant heat or a stray spark.

- Conduct regular safety reviews and family education. All members of the household who may operate or be near the stove should understand its basic operation and the fundamental safety rules. A brief, periodic review of how to properly light, adjust, and extinguish the stove, along with a discussion of what to do in an emergency, ensures everyone is a participant in maintaining a safe environment.

Emergency Response Preparedness

Despite all precautions, preparedness for a potential incident is a critical component of safety. The correct equipment and knowledge can prevent a small incident from becoming a major disaster.

Fire Safety Equipment Requirements

Having the proper fire suppression tools immediately accessible and knowing how to use them is non-negotiable.

- Keep a Class B fire extinguisher accessible near the operating area. Class B extinguishers are rated for flammable liquid and gas fires, which is exactly the hazard presented by a kerosene spill or stove malfunction. It should be mounted on a wall within easy reach, but not so close that you would have to reach over the fire to access it. Ensure everyone knows its location.

- Understand the proper use of fire blankets for fuel fires. A fire blanket can be highly effective for smothering a small, contained fire, such as one in the stove’s burner cup or a small fuel spill. The blanket should be carefully placed over the entire base of the flames to cut off the oxygen supply. Do not throw it, as this can splash burning fuel.

- Never use water on a kerosene fire. This is a fundamental and critical rule. Water is heavier than kerosene and will sink, causing the burning fuel to splatter and spread, dramatically enlarging the fire and increasing the danger. Your response must be based on smothering the flames (with a Class B extinguisher or fire blanket) or depriving them of oxygen, not dousing them with water.

Integrating these habits and tools into your home safety plan is essential. For households seeking a stove designed with these safety principles in mind, the 2025 EcoBlaze Portable Stove includes features like a stable, wide base and a built-in safety shut-off. To see how its design supports a comprehensive safety culture, more details are available at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Understanding the Risks: Why Kerosene Stove Safety Matters】

The principles of a safety culture are built upon a clear-eyed understanding of what can go wrong. For kerosene stoves, the potential hazards are not abstract; they are specific, well-documented, and stem from a combination of equipment condition and fuel quality. Recognizing these risks is the first and most critical step toward mitigating them.

The Alarming Statistics of Kerosene-Related Injuries

Data from public health and safety agencies paints a stark picture of the consequences when kerosene stove safety is compromised. The numbers are not merely statistics but represent preventable tragedies that underscore the non-negotiable need for vigilance.

Burn Injury Data Analysis

The link between kerosene stove malfunctions and severe injury is undeniable. A 2025 analysis of burn center admissions across the Indian subcontinent revealed a sobering trend: approximately 40% of all severe burn injuries were directly attributable to kerosene stove explosions and flare-ups. The root causes identified in these incidents follow a consistent pattern:

| Root Cause | Frequency in Incident Reports | Typical Consequence |

|---|---|---|

| Overpressure in Fuel Tank | High | Explosive fuel ejection and fireball |

| Use of Nonstandard/Adulterated Equipment | Very High | Uncontrolled combustion and tank rupture |

| Wear from Corrosion | Moderate to High | Fuel leaks and structural failure of tank |

Furthermore, post-accident investigations consistently point to poor maintenance of burners and fuel tanks as a primary contributing factor. The gradual, often invisible, degradation of critical components creates a latent failure point that can culminate in a catastrophic event.

Common Hazard Sources in Kerosene Stoves

To manage risk effectively, one must know where to look. The primary dangers in kerosene stove operation originate from two key areas: the quality of the fuel and the integrity of the equipment itself.

Fuel Contamination Dangers

The chemical stability of kerosene is fundamental to safe combustion. When this stability is compromised, the risk of explosion increases exponentially.

- Adulteration with Volatile Spirits: A common and extremely dangerous practice is the dilution of kerosene with more volatile fuels such as gasoline or alcohol. These substances have a much lower flashpoint, creating a highly explosive mixture within the pressurized tank that can ignite with violent force.

- Use of Impure Kerosene for Preheating: Some stoves require a small amount of fuel in the burner cup for preheating. Using contaminated or impure kerosene here can lead to unpredictable, large flames during the lighting process, potentially igniting fuel vapors or nearby combustibles.

- Unfiltered Kerosene: Dirt, sediment, and other particulates in fuel are a primary cause of clogged fuel nozzles and vaporizers. A clogged component disrupts the fine mist of fuel required for clean combustion, leading to irregular flames, flare-ups, and the dangerous release of unburned fuel.

Equipment Failure Points

The mechanical integrity of the stove is your first line of defense. When key components fail, they often do so without warning.

- Missing or Faulty Pressure Indicators: Many pressurized stoves are equipped with a pressure gauge. A missing or broken gauge removes the operator’s ability to monitor internal tank pressure, allowing dangerous overpressure situations to develop, which can rupture the tank or force excess fuel into the burner.

- Corroded Stove Bodies: External and internal corrosion, often accelerated by fuel spills and moisture, progressively weakens the metal of the fuel tank and stove body. This compromises its structural integrity, making it susceptible to cracks or rupture under normal operating pressure.

- Damaged Air Pumps with Poor Seal Standards: The air pump is critical for maintaining steady pressure. A pump with worn leather seals, a cracked shaft, or a damaged check valve will lead to pressure inconsistencies. This results in an uneven flame, difficult ignition, and the risk of the flame sputtering out while fuel continues to flow.

Adherence to strict maintenance protocols is the most effective defense against these failure points. For those seeking a stove engineered to minimize these risks, the 2025 EcoBlaze Portable Stove features a corrosion-resistant body and a precision fuel filtration system. To explore its safety-oriented design, visit: https://www.ecoblaze-stoves.example/kerosene-safety.

【Proper Cleaning Procedures: Maintaining Optimal Performance】

The statistical risks outlined in the previous section are not inevitable. They are, in large part, the consequence of neglected maintenance. A rigorous and consistent cleaning regimen is the most powerful tool for preventing the equipment failures and combustion irregularities that lead to accidents. Proper maintenance is not merely about cleanliness; it is a systematic approach to preserving the stove’s engineered safety margins.

Daily Cleaning Protocol

A brief, disciplined routine performed after each use forms the foundation of stove safety. This protocol focuses on the components most immediately affected by combustion: the burner and the wick.

Burner Nozzle Maintenance

The burner nozzle is the final gateway for fuel before it vaporizes and ignites. Its condition dictates the quality and safety of the flame.

- Use of Specified Cleaning Pins: The nozzle’s orifice is precision-drilled. Using improvised tools like wires or needles can permanently enlarge or scratch it, disrupting the fine fuel spray. This leads to an erratic, smoky flame and increased carbon buildup. Always use the manufacturer-provided pin.

- Removal of Carbon Deposits: After the stove has completely cooled, the nozzle should be cleaned of any carbon residue. A clogged or partially blocked nozzle causes uneven fuel distribution, leading to flame flicker, flare-ups, and the release of unburned hydrocarbons.

- Proper Wick Trimming: For wick-type stoves, the wick tip must be trimmed flat and even after cooling. A jagged or uneven wick creates multiple flame points, resulting in incomplete combustion, excessive smoke, and carbon monoxide production. A flat wick promotes a single, stable, and efficient blue flame.

Tank Cleaning Requirements

The integrity of the fuel tank is paramount to preventing leaks and overpressure events. Contamination inside the tank is a slow-moving threat.

- Periodic Rinsing: Every few weeks, or whenever changing fuel brands, the tank should be emptied and rinsed with a small amount of clean kerosene. Swirl the kerosene inside to dislodge any sediment or water contamination, then dispose of the rinsate safely. This prevents the accumulation of sludge that can clog the fuel line.

- Regular Inspection for Rust: During rinsing, visually inspect the tank’s interior for signs of rust or corrosion. Internal rust flakes can travel into the fuel line and nozzle, causing blockages. External rust weakens the tank’s structural integrity.

- Proper Filtration Before Refilling: This is a non-negotiable step. Always filter kerosene through a fine mesh or water-separating filter funnel when refilling the tank. This is the primary defense against introducing the particulates and moisture that lead to clogged nozzles and internal corrosion.

Weekly Deep Cleaning Process

A more thorough weekly disassembly and cleaning addresses the cumulative byproducts of combustion that daily cleaning cannot reach.

Combustion Chamber Maintenance

The combustion chamber is where fuel and air mix to create flame. Its condition directly impacts combustion efficiency and safety.

- Removal of Soot Buildup: Soot is a sign of incomplete combustion. A thick layer of soot inside the chamber acts as an insulator, causing the stove to overheat and potentially damaging components. It can also flake off and block air vents or the burner. Use a soft brush and cloth to remove all soot deposits.

- Inspection of Seals and Gaskets: With the chamber exposed, carefully inspect all rubber or fiber seals and gaskets, particularly those around the fuel line connections and between the tank and the burner assembly. Look for cracking, brittleness, or flattening. A compromised seal will allow fuel to leak, creating a severe fire hazard.

- Verification of Air Mixture Settings: Check that the air shutter or mixture control is clean, moves freely, and is set according to the manufacturer’s specifications. An incorrect air-to-fuel ratio is a primary cause of sooty flames (too little air) or loud, unstable combustion (too much air).

Adhering to this cleaning hierarchy—daily attention to the burner and weekly care of the combustion system—is the cornerstone of operational safety. For stove owners who value a design that simplifies this essential maintenance, the 2025 EcoBlaze Portable Stove features a quick-disassembly combustion chamber and a built-in, replaceable fuel filter. To learn more about its user-serviceable design, visit: https://www.ecoblaze-stoves.example/kerosene-safety.

【Safe Operation Practices: Preventing Common Accidents】

The meticulous cleaning protocols previously detailed are a defensive measure against the gradual degradation of your stove. However, the most immediate dangers often arise from operational errors. Safe operation is an active practice, a series of deliberate choices that form a protective barrier between controlled utility and preventable disaster.

Fuel Handling and Storage Guidelines

The quality and handling of the fuel itself are foundational to safe stove operation. Compromised fuel can render even the most well-maintained stove unsafe.

Proper Fuel Selection and Storage

The wrong fuel or aged fuel introduces risks that no amount of cleaning can mitigate.

| Practice | Rationale & Safety Impact |

|---|---|

| Use only 1-K grade kerosene | 1-K grade is specially refined for indoor, unvented appliances. It has low sulfur content, minimizing the production of sulfur dioxide (SO₂) and soot. Using cheaper 2-K grade or other fuels like diesel or gasoline is extremely hazardous, producing toxic fumes and creating excessive carbon buildup. |

| Store in approved, labeled containers | Use containers certified for kerosene storage, typically blue to distinguish them from gasoline (red) or diesel (yellow). These containers are designed to withstand fuel corrosion and manage pressure changes, reducing the risk of leaks and vapor accumulation. |

| Implement first-in, first-out (FIFO) rotation | Kerosene degrades over time, absorbing moisture from the air which leads to microbial growth (“kerosene fungus”) and tank corrosion. Using the oldest fuel first and purchasing only what you will use in a few months ensures cleaner combustion. |

| Store in a cool, well-ventilated location | Keep fuel containers away from living areas, water heaters, furnaces, or any other source of heat or flame. A detached, well-ventilated shed is ideal. This prevents pressure buildup in containers and eliminates the risk of vapor ignition. |

Refueling Safety Procedures

Refueling is a high-risk moment where fuel is exposed and the potential for spillage and ignition is greatest.

- Refill Outdoors and After Cooling: Always move the stove outside to refuel, and only after it has cooled completely to the touch. Adding cold fuel to a warm tank can cause dangerous fuel vapors to expand and escape. An outdoor location ensures any spilled fuel or vapors dissipate safely.

- Eliminate All Ignition Sources: Before refueling, ensure there are no open flames, active pilot lights, or sparks in the vicinity. Do not smoke.

- Use a Filter Funnel: This step is as crucial for safety as it is for maintenance. A fine mesh or water-separating filter funnel prevents sediment and water from entering the tank, which are common causes of nozzle clogs and irregular, unsafe flames. It also minimizes spills.

Operational Safety Measures

Once the stove is fueled and assembled, its safe use depends on respecting its physical limits and the principles of combustion.

Preventing Overpressure Situations

Overpressurization of the fuel tank is a primary cause of flare-ups and, in severe cases, explosive fuel ejection.

- Dispelling the “More Pump, More Heat” Myth: The hand pump is used to create initial pressure to lift fuel to the burner. Once a stable flame is achieved, excessive pumping does not significantly increase heat output. Instead, it forces an excessive amount of raw, unvaporized fuel into the burner assembly. This fuel can pool, ignite unpredictably, and create a fireball. Pump only as directed in the manufacturer’s instructions.

- Utilize Pressure Safety Features: Many modern stoves are equipped with pressure relief valves or automatic pressure regulators. These are critical safety components. Never disable or modify these features. If your stove lacks one, consider upgrading to a model that includes this protection.

- Monitor Flame Characteristics: A safe, efficient flame is predominantly blue and quiet. A loud, roaring, or predominantly yellow flame is a clear indicator of excessive pressure and/or an incorrect air-fuel mixture. Immediately turn off the stove, release excess pressure from the tank, and re-light once the flame characteristics can be stabilized.

Cookware and Setup Considerations

The stove’s immediate environment is part of the safety system. Poor setup can undermine the stove’s designed operation.

- Avoid Oversized Cookware: Using a pot that completely covers the stove or extends far beyond the burner head disrupts the essential airflow required for complete combustion. This leads to oxygen starvation, producing copious amounts of carbon monoxide and soot. Ensure there is a clear space around the burner assembly.

- Stable, Non-Flammable Placement: Operate the stove only on a stable, level, and non-combustible surface, such as a ceramic tile or a dedicated metal counter protector. This prevents tipping and protects the underlying surface from conducted heat, which can be sufficient to ignite wood or laminate countertops.

- Maintain a Clear Zone: Establish a minimum one-meter safety perimeter around the operating stove, free from curtains, paper towels, food packaging, and other flammable materials. This provides a buffer zone against accidental contact and airborne sparks.

Adherence to these operational disciplines transforms routine use from a potential hazard into a controlled, safe activity. For those seeking a stove engineered with these principles at its core, the 2025 EcoBlaze Portable Stove incorporates an automatic pressure regulator to eliminate overpressure risks and a stable, wide-base design to prevent tipping. Its design philosophy prioritizes operational safety without compromising performance. To explore its full range of safety features, visit: https://www.ecoblaze-stoves.example/kerosene-safety.

【Ventilation and Air Quality Management】

The safe operation of a kerosene stove extends beyond preventing immediate fire hazards; it fundamentally involves managing the invisible byproducts of combustion. Proper ventilation is not a mere suggestion but a critical life-safety system. It ensures that the combustion process, which consumes oxygen and produces gases, remains contained and controlled, protecting the air you breathe from dangerous contamination.

Combustion Spillage Prevention

Combustion spillage occurs when the byproducts of burning fuel—including carbon monoxide (CO), carbon dioxide (CO₂), water vapor, and nitrogen oxides—are not properly vented outdoors and instead “spill” back into the living space. This is often a consequence of negative indoor air pressure.

Understanding Backdrafting Risks

Backdrafting is the dangerous phenomenon where combustion gases are pulled back into the home instead of being expelled. This is typically caused by a negative pressure differential, meaning the air pressure inside the home is lower than the pressure outside.

- Recognize Symptoms of Negative Pressure: Be alert to signs that your home is under negative pressure. These include:

- Difficulty in opening or closing exterior doors.

- A fireplace that smokes or downdrafts when lit.

- The sensation of air being sucked in through window cracks.

- The persistent operation of high-power exhaust fans (e.g., in a large kitchen range hood or a whole-house bathroom fan) can create this condition.

- Install Carbon Monoxide Detectors: This is a non-negotiable safety measure. Install battery-operated or plug-in CO detectors on every level of your home, especially near sleeping areas. Carbon monoxide is odorless and colorless, and a detector is the only reliable way to alert you to its presence. Test them monthly and replace batteries as needed.

- Ensure Adequate Makeup Air: For a kerosene stove to burn safely, it requires a constant supply of fresh air (makeup air). In a tightly sealed modern home, running a stove can rapidly deplete oxygen. Always open a window slightly in the room where the stove is operating, preferably on the opposite side of the room to create cross-ventilation. This provides the necessary oxygen for combustion and prevents the formation of negative pressure.

Ventilation Requirements

Active ventilation is your primary tool for diluting and removing combustion byproducts.

- Maintain Cross-Ventilation: Simply opening a window is not always sufficient. To effectively prevent fume accumulation, create a cross-breeze by opening windows or vents on opposite sides of the room. This allows fresh air to enter and contaminated air to be forced out, rather than allowing fumes to stagnate.

- Monitor for Symptoms of Carbon Monoxide Exposure: Early signs of CO poisoning are often flu-like and can be mistaken for other illnesses. Be vigilant for symptoms such as headache, dizziness, nausea, shortness of breath, and confusion. If multiple people in the household experience these symptoms simultaneously when the stove is in use, immediately turn off the stove, evacuate to fresh air, and seek medical attention.

- Understand the Relationship Between House Tightness and Combustion Safety: Modern, energy-efficient homes are built to be exceptionally airtight. While this saves on energy costs, it severely compounds the risks of using any unvented combustion appliance. The safer the house envelope, the more deliberate and robust your active ventilation strategy must be when operating a kerosene stove indoors.

Indoor Air Quality Protection

The goal is not only to prevent acute poisoning but also to minimize chronic exposure to lower levels of combustion pollutants that can aggravate respiratory conditions.

Toxic Fume Reduction Strategies

A well-maintained stove and proper usage are the first lines of defense in protecting indoor air quality.

- Regular Maintenance Minimizes Carbon Monoxide Production: A clogged wick, a dirty burner head, or an over-pressurized tank forces the stove to burn inefficiently. Incomplete combustion is the primary source of carbon monoxide. The meticulous cleaning and adjustment protocols discussed earlier are, therefore, direct interventions for air quality protection.

- Proper Wick Adjustment Reduces Particulate Matter Emission: A wick that is set too high will produce a smoky, sooty flame, releasing fine particulate matter (PM2.5) into the air. These particles can penetrate deep into the lungs. A clean, correctly trimmed wick producing a sharp, blue-tipped flame is the hallmark of clean combustion and minimal particulate emission.

- Adequate Ventilation Dilutes Combustion Byproducts: Even a perfectly operating kerosene stove produces carbon dioxide, water vapor, and small amounts of nitrogen dioxide. Without adequate ventilation, CO₂ levels can rise, leading to drowsiness and reduced cognitive function, while excess humidity can promote mold growth. Continuous fresh air exchange is essential to keep these byproducts at safe and comfortable levels.

For homeowners seeking to minimize these inherent risks, modern stove designs offer significant improvements. The 2025 EcoBlaze Portable Stove, for instance, is engineered with a catalytic converter that significantly reduces carbon monoxide and particulate emissions compared to conventional models. Its efficient burner design promotes more complete combustion, contributing to better indoor air quality when used with proper ventilation. To learn more about its emission control technology, you can review the specifications at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Emergency Preparedness and Response】

While diligent maintenance and ventilation are the cornerstones of prevention, a clear plan for potential emergencies is the final, critical layer of safety. Understanding how to recognize imminent danger and how to respond effectively can prevent a manageable incident from becoming a catastrophe.

Fire Prevention Measures

Preventing a fire requires constant vigilance for the subtle warning signs that precede a major incident. These indicators often manifest as deviations from the stove’s normal, stable operation.

Recognizing Pre-Explosion Indicators

A kerosene stove does not typically “explode” without warning. It is usually preceded by a series of malfunctions that, if recognized, provide a crucial window for intervention.

- Identify unusual sounds indicating pressure buildup: A healthy stove operates with a steady, low hum from the burner. Be acutely aware of any new or changing sounds. A hissing or sputtering noise may indicate a clogged fuel line or a malfunctioning tank valve leading to irregular fuel flow or vapor release. A popping sound can signal a sudden flare-up or ignition of built-up fumes.

- Recognize irregular flame patterns suggesting combustion problems: The ideal flame is steady, even, and has distinct blue cones with yellow tips. Any significant deviation is a cause for immediate concern. A floating or “lazy” yellow flame indicates incomplete combustion, often due to a dirty wick or air intake. A pulsating or “roaring” flame suggests too much fuel or air, creating an unstable burn. The most dangerous sign is flame rollout—where fire escapes from the burner assembly—which requires instant shutdown.

- Detect fuel odors signaling leakage or incomplete combustion: A faint odor upon lighting or extinguishing the stove can be normal. However, a persistent, strong smell of kerosene during operation is a major red flag. It can indicate a physical leak from the tank, fuel line, or seals, or it can mean the fuel is not being fully vaporized and burned, leading to fume accumulation. In either case, the stove should be turned off immediately, the area ventilated, and the unit inspected before further use.

Emergency Response Protocols

When a warning sign escalates into an active emergency, a calm and practiced response is essential. Every individual in the household should be familiar with these protocols.

Immediate Action Procedures

Speed and correctness of action are paramount. The following steps should be committed to memory.

- Evacuation protocols for suspected gas accumulation: If you suspect a significant fuel leak or the presence of carbon monoxide (as indicated by a detector alarm or symptoms like dizziness and nausea), prioritize evacuation. Do not turn electrical switches on or off, as a spark could ignite vapors. Get everyone out of the house immediately to a predetermined safe location outside and call emergency services from there.

- Proper fire extinguisher selection for fuel fires (Class B): Always keep a charged, readily accessible fire extinguisher rated for Class B (flammable liquids) fires. A multipurpose ABC extinguisher is also acceptable. Do not use water on a kerosene fire, as it will cause the burning fuel to spread. Remember the PASS technique: Pull the pin, Aim at the base of the fire, Squeeze the handle, and Sweep from side to side.

- Emergency shutdown procedures for various scenarios:

- For a contained stove fire: If it is safe to do so, immediately turn off the stove’s fuel control knob to stop the flow of fuel.

- For a larger fire or leak: If the fire is spreading or a leak is uncontrolled, evacuate immediately. If you can do so safely on your way out, shut off the main fuel supply valve on the kerosene container.

First Aid for Kerosene-Related Injuries

Prompt and proper first aid can significantly improve outcomes for burns and inhalation injuries while awaiting professional medical help.

- Burn treatment protocols for different severity levels:

- First-Degree Burns (redness, minor pain): Cool the burn with cool (not ice-cold) running water for 10-15 minutes. Cover with a sterile, non-adhesive bandage.

- Second-Degree Burns (blisters, severe pain): Do not break blisters. Cool with water. loosely cover with a sterile dressing. Seek medical attention.

- Third-Degree Burns (white or charred skin, may be little pain due to nerve damage): Do not cool with water. Cover the area lightly with a sterile non-stick dressing. Call for emergency medical help immediately.

- Inhalation exposure response measures: Move the affected person to fresh air immediately. Loosen any tight clothing around the neck and chest. If the person is not breathing and you are trained, begin CPR. Administer oxygen if it is available. Even if the person recovers quickly, seek medical evaluation, as the effects of carbon monoxide poisoning can be delayed.

- Emergency contact and medical response coordination: Keep the national or local poison control center and emergency medical services numbers readily available. When calling, be prepared to state the nature of the emergency (e.g., “kerosene fire,” “carbon monoxide exposure”) and the number and condition of the victims.

A well-equipped household is a safer one. Keeping a 2025 EcoBlaze Safety Kit, which includes a Class B fire extinguisher, a carbon monoxide detector with a digital display, and a burn first aid kit, ensures you have the essential tools for emergency response within reach. This kit is designed to complement the safety features of modern stoves. You can find more details on its contents at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Equipment Selection and Maintenance Schedule】

The foundation of safety with a kerosene stove is established long before it is ever lit. It begins with the deliberate selection of well-engineered equipment and is sustained through a rigorous, documented maintenance schedule. This disciplined approach transforms the stove from a potential hazard into a reliably controlled tool.

Choosing Safe Kerosene Stoves

Selecting a stove is not merely a matter of cost or convenience; it is a critical safety decision. The market offers a wide range of models, but only those with specific, non-negotiable features should be considered for household use.

Critical Safety Features

When evaluating a kerosene stove, prioritize these fundamental safety engineering elements:

- Pressure relief mechanisms as standard equipment: The fuel tank is a pressurized vessel. A functional pressure relief valve is essential to prevent catastrophic tank failure from over-pressurization, which can be caused by overfilling or excessive heating. This feature is a primary defense against rupture.

- Durable metal construction without plastic components: The stove’s core structure, especially the fuel tank and burner assembly, must be constructed of robust, heat-resistant metal. The presence of plastic in these critical areas is a significant liability, as it can melt, crack, or degrade over time, leading to fuel leaks and fire.

- Adequate manufacturer testing and certification: Prioritize stoves from manufacturers that subject their products to independent testing and adhere to recognized national or international safety standards. Look for certification marks from reputable bodies, which provide assurance that the stove has been evaluated for risks like flame stability, fuel leakage, and pressure integrity.

Equipment Specifications

Beyond core features, specific design choices can significantly influence the stove’s operational safety and long-term reliability.

- Single burner designs preferred over double burner models: While double-burner stoves offer convenience, single-burner units are inherently safer. They are simpler, have fewer points of potential failure, generate less concentrated heat, and are easier to manage and move. For most household needs, the reduced complexity of a single burner is a worthwhile safety trade-off.

- Standardized components for reliable replacement parts: A stove is only as safe as its most worn part. Choose models for which consumable components like wicks, washers, and seals are standardized and readily available. The inability to replace a worn gasket with an exact, manufacturer-approved part can lead to dangerous improvisation.

- Manufacturer compliance with safety standards: This is not an abstract concept. Compliance should be verifiable through user manuals that clearly outline safety procedures, warnings, and specifications. A manufacturer’s commitment to documentation is a proxy for their commitment to safety engineering.

Maintenance Scheduling and Documentation

The safest stove will become hazardous if neglected. Adherence to a strict maintenance schedule is not optional; it is the practice that keeps the theoretical safety of the equipment a daily reality.

Daily Inspection Checklist

This brief pre-use inspection takes less than a minute but is the most effective daily practice for catching problems before they escalate.

| Task | Acceptable Condition | Action if Unacceptable |

|---|---|---|

| Visual exam for leaks, rust, damage | No visible fuel moisture, corrosion, or dents on tank or fuel lines. | Do not use. Tag for repair or replacement. |

| Verification of stable platform placement | Stove is on a flat, level, non-flammable surface, away from edges. | Reposition the stove before lighting. |

| Confirmation of adequate ventilation | Window or vent is open to provide cross-ventilation. | Increase ventilation before proceeding. |

Monthly Maintenance Tasks

Once a month, or after every 20-30 hours of use, the stove requires a more thorough disassembly and cleaning to ensure all components are functioning correctly.

- Complete disassembly and thorough cleaning: Following the manufacturer’s instructions, fully disassemble the stove. Clean all components with warm, soapy water, ensuring all old fuel residue, carbon deposits, and dust are removed from the burner assembly, vaporizing tube, and tank. Rinse and dry all parts completely before reassembly.

- Wick replacement and nozzle inspection: If your model has a wick, inspect it for charring, uneven burning, or a hardened tip. Trim it to the manufacturer’s specified height or replace it entirely if it is heavily degraded. For wickless models, inspect the vaporizing nozzle for any clogs or damage, cleaning it with an appropriate tool as per the manual.

- Pressure testing and seal verification: After reassembly, pressurize the tank and apply a soapy water solution to all seals, joints, and the tank cap. The formation of bubbles indicates a leak. All seals and gaskets showing signs of wear, hardening, or leakage must be replaced immediately with manufacturer-approved parts.

Adhering to this schedule requires the right tools and consumables. Using a 2025 EcoBlaze Maintenance Kit, which includes genuine replacement wicks, a full set of seals and gaskets, and specialized cleaning tools, ensures that your monthly maintenance is performed to the highest standard. This kit is designed for use with EcoBlaze stoves and other major brands with standardized parts. You can review the kit’s components and ordering information at: https://www.ecoblaze-stoves.example/kerosene-safety.

【Long-Term Safety and Efficiency Optimization】

The initial selection of a well-engineered stove and adherence to a disciplined maintenance schedule establish a baseline of safety. However, the true test of stewardship lies in managing the stove’s long-term, progressive deterioration. A stove that appears functional can harbor hidden inefficiencies and risks that accumulate over months and years. A proactive, systematic approach is required to optimize its performance and ensure its safety over its entire operational lifespan.

Preventing Progressive Deterioration

The primary enemy of a kerosene stove’s longevity is corrosion. This is not merely surface rust; it is a systemic degradation that can compromise the structural integrity of the fuel tank and burner assembly, leading to catastrophic failure.

Corrosion Prevention Strategies

Combating corrosion requires a multi-pronged strategy focused on interrupting the chemical processes that cause metal to fail.

- Regular cleaning to remove acidic combustion residues: After each use, and especially during the monthly deep clean, it is critical to thoroughly remove all soot and carbon deposits. These residues are often slightly acidic and, when combined with atmospheric moisture, create an electrolyte that dramatically accelerates the corrosion of metal surfaces. A clean stove is a more durable stove.

- Proper storage to minimize moisture exposure: When the stove is not in use, particularly for extended periods, storage conditions are paramount. The stove must be stored in a cool, dry place with low humidity. It should be completely empty of fuel, as old kerosene can degrade and form corrosive by-products. The storage area should be free from temperature fluctuations that can cause condensation to form inside the tank.

- Protective coatings for vulnerable metal components: For external metal surfaces not directly exposed to the flame, a thin application of a high-temperature resistant oil or silicone-based spray can provide a protective barrier against moisture. Internally, ensuring the tank is drained and dry is the best protection. Never use paints or unapproved coatings on or near the burner assembly, as they may combust or release toxic fumes.

Efficiency Maintenance

An inefficient stove is not just wasteful; it is often an unsafe stove. Incomplete combustion, signaled by a yellow or sooty flame instead of a crisp blue one, produces excessive carbon monoxide and unburned hydrocarbon particulates. Maintaining peak efficiency is therefore a core safety function.

Combustion Optimization

Efficiency is a measurable variable, not a subjective feeling. It requires regular monitoring and adjustment.

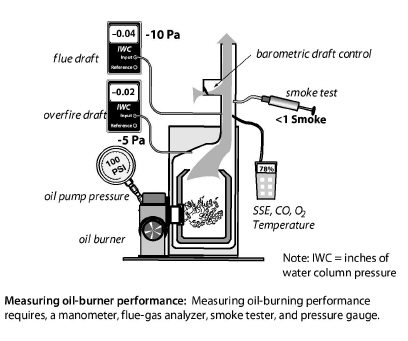

- Regular adjustment of air-fuel mixture for complete combustion: Most stoves have an adjustable air intake or shutter. Refer to the manufacturer’s manual to correctly adjust this for a clean, blue flame. A yellow, smoky flame indicates insufficient air, leading to incomplete combustion and carbon monoxide production. An overly lean mixture (too much air) can cause unstable, lifting flames.

- Monitoring of fuel consumption patterns for efficiency tracking: Keep a simple log of hours of use versus fuel consumed. A sudden, unexplained increase in fuel consumption for the same cooking output is a critical indicator of an underlying problem, such as a clogged nozzle, a degraded wick, or a microscopic fuel leak.

- Temperature output verification for consistent performance: Using an infrared thermometer to periodically check the flame temperature can provide an objective measure of combustion efficiency. A significant drop from the stove’s specified output indicates a need for servicing or component replacement.

Safety System Verification

The safety features that were decisive in your initial equipment selection must be periodically validated to ensure they have not degraded over time. Their failure often goes unnoticed until the moment they are critically needed.

- Periodic testing of pressure relief mechanisms: Every six months, the pressure relief valve should be tested according to the manufacturer’s instructions. This typically involves pressurizing the tank and manually activating the valve to confirm it opens and closes at the specified pressure and reseals properly. A valve that fails to open or that leaks after closing must be replaced immediately.

- Validation of automatic shutdown features: If your stove is equipped with a tip-over automatic shutoff, test this function monthly. Carefully and safely tilt the stove to its activation angle and verify that the fuel supply is cut off and the flame is extinguished. Ensure the mechanism resets correctly for the next use.

- Confirmation of structural integrity through stress testing: During the monthly disassembly, pay close attention to the integrity of the fuel tank. Look for any signs of bulging, deep pitting, or hairline cracks, especially around seams and welded joints. Gently pressurize the empty tank and listen for any hissing that might indicate a pinhole leak not visible to the eye.

This long-term optimization relies on high-quality consumables and a disciplined verification schedule. The 2025 EcoBlaze Maintenance Kit includes corrosion-inhibiting cleaning solutions, a full set of pressure-testing gaskets, and a guide for calibrating air-fuel mixture, providing the necessary tools for this advanced level of care. For models with integrated safety shutoffs, the kit also contains replacement parts to restore these critical functions. Ensure your stove’s long-term reliability by using components designed for it: https://www.ecoblaze-stoves.example/kerosene-safety.

Your Path to Uncompromised Kerosene Stove Safety

Mastering kerosene stove operation is built on a foundation of disciplined practices. We’ve detailed the non-negotiable pillars: rigorous daily and weekly cleaning to prevent clogs and corrosion, the exclusive use of pure K-1 kerosene to ensure clean combustion, and the absolute requirement for active ventilation paired with a working carbon monoxide detector. Furthermore, maintaining a clear safety perimeter, never leaving the stove unattended, and having a Class B fire extinguisher ready are essential habits that define a comprehensive safety culture. Consistency in these areas is your most powerful defense against the primary risks of fire, explosion, and toxic fume inhalation.

Safety is an active commitment, not a passive state. By integrating these protocols into your routine, you take full control of your household’s well-being. This knowledge empowers you to operate your stove with confidence, but the responsibility to apply it rests with you. We are committed to supporting your journey towards complete safety.

Have you successfully implemented a new safety step from this guide? Share your experience or ask a question in the comments below to help build a community of safe and informed users. Your insights could be invaluable to others.